Bridge Aqueducts & Metroline

Metro line

Design and retrofitting of RCC Cross Girders at Metro line Stations

Problem:

- Structural retrofitting of cross girders was required due to a construction error.

Solution:

- 24 cross girders were retrofitted after carrying out design analysis.

- Work involved Grouting and section built-up with micro-concrete

- Application of carbon fiber laminate and wraps as per design

The job was carried out in short time intervals of 2 to 3 hours in late night hours. Traffic management on roads below metro lines was a major challenge. Full scale load testing was done successfully.

Purnia Bridge, Bihar

Structural repairs of an Under construction Bridge in Purnia Bihar

Problem:

- Dense reinforcement at the bottom of a cast in-situ girder resulted in heavy honey combing or hollow bottom section of the girder after casting.

Solution:

- Loose concrete was removed until only sound concrete is left.

- Hollow section was rebuilt using micro-concrete

- Gap between the two was filled by epoxy grouting

- A layer of CFRP wrap was applied on the girder section that was repaired and applied with protective PU coat

Chehru bridge on NH-01, Punjab

Structural repair and retrofitting of Chehru bridge on NH-01

Problem:

- Structural repair and retrofitting were required after 25 years of commissioning.

Solution:

- Sand blasting, crack filling and epoxy grouting.

- Application of prestressed precured carbon laminate plates along with fiber wrapping work on all 8 spans of 29m each.

- Sanrachana delivered this project successfully in a time of 4.5 months

After completion of the retrofitting work the bridge was successfully tested for IRC Class 70 R loading condition. Chehru bridge on NH-01 part of the original Grand Trunk Road is a vital link between Jalandhar and Phagwara in Punjab

Aquaduct at Tawa Canal, MP

Aquaduct at Tawa Canal Division

Problem:

- It was required to augment the durability aspect of the aquaduct. MP WRD had undertaken strengthening of the piers of Ganjal Aqueduct at Tawa left bank main canal.

Solution:

- Excavation to expose the piers

- Polymer plaster for section built-up

- Application of 22,000 sqm of carbon fiber wraps in two layers, plastering and painting

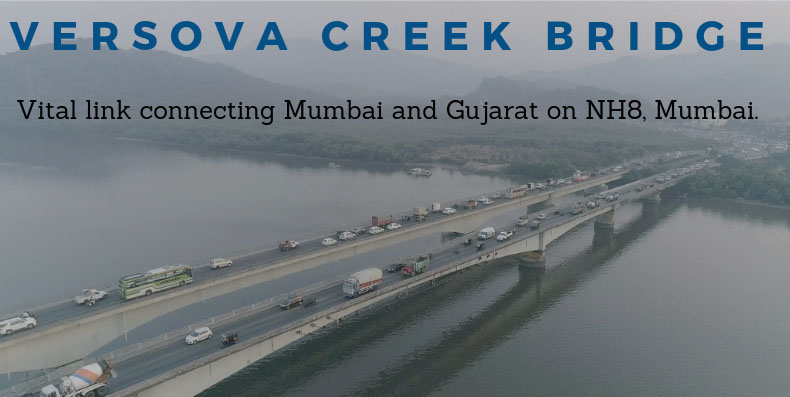

VERSOVA CREEK BRIDGE

Problem:

- Central balanced cantilever of 110 m span was showing major distresses

Solution:

- Conventional epoxy grouting was applied along with epoxy mortar repairs

- External post tensioning was used to counteract the large forces across cantilevered portion

- Application of high modulus carbon fiber laminates and carbon fiber wrapping as per design

The bridge connects Mumbai and Gujarat, making it an essential link in NH8. Apart from Sanrachana, experts like IIT Bombay, Ramboll, SMC and IRB were involved with NHAI on this project.

RESTORING RCC AQUEDUCT

Structure:

50 years old RCC aqueduct in Madhya Pradesh (Central India). Longest aqueduct carrying water in the region

Problem:

- Corrosion of steel reinforcement

- Erosion of foundation

- Seepage through expansion joints

- Canal cannot be used to its full capacity leading to water shortage

- Creating farmer unrest in near by area

Solution:

- Treating steel with rust converting primer

- Application of corrosion inhibitors, grouting

- Rebuilding sections using Thixotropic mortars and mico-concrete,

- Stone masonry for protection against scouring

- Treatment of expansion joints to arrest seepage

- CFRP Wrapping on piers

- Canal brought back to its full capacity in 6 months

One of the Largest CFRP – SRM – CWrap 200 – application on any single project – 22000 sq. meters of wrapping on piers and different RCC elements.

RESTORING CADBURY BRIDGE

Problem:

Cracks of varying intensity observed in almost all 10 girders per span, in the nearly 60 span 1.5km flyover on Eastern Express Highway

Diagnosis:

Cracks in girder were primarily due to reduced shear capacity, causing combined shear-flexure cracks. Alligator cracks seen in slab were to be sealed to prevent corrosion damage in future.

Solution:

- Categorizing girders based on extent of distress

- Applying prestressed carbon-fiber laminates for counteracting flexural and shear forces

- Applying U shaped carbon fiber sheets parallel to stirrups for additional shear strength

FIRST OVERSEAS CHAPTER: ETHIOPIA

Problem:

Analysis and NDT revealed severe steel deficiency in piers and cross-girders of this bridge. A new steel pedestrianfootpath was meant to be anchored to the structure. Overall steel deficiency and additional loads of footpath was to be tackled.

Solution:

- NSM application of SRM-C-Lam 100×3 carbon fiber laminates on column, by groove cutting.

- Confinement of columns after SRM-C-Lam application, using SRM-C-900 CFRP wrapping

- SRM-C laminates to act as external tensile reinforcement for the cross girders

- Steel plate anchoring and SRM-C-600 U-wrap for effective end confinement in cross girders.